What is an electrical transformer? It’s a device crucial to modern life, transforming voltage levels to ensure the safe and efficient flow of electricity from power stations to your wall outlet. Simple in theory yet intricate in design, transformers use electromagnetic induction to either ramp up or reduce voltage, serving as the backbone of electrical grids worldwide. Our guide will unveil how they work, their different types, and their role in your daily life without overwhelming you with technicalities.

Key Takeaways

- Electrical transformers are pivotal equipment that convert high-voltage power to lower, safer voltages for use, primarily through electromagnetic induction, and exist in various types, each serving specific functions.

- Transformers are comprised of critical components such as the core, windings, insulating materials, and transformer oil, essential for efficient and safe operation; routine maintenance and proper installation are crucial for longevity and optimal functionality.

Unveiling the Electrical Transformer

An electrical transformer, such as the green transformer box you might see in your yard, is a vital piece of electrical equipment. It serves a fundamental purpose of converting high-voltage power to a lower voltage that is safe for distribution and usage in our homes and businesses. This conversion is accomplished through a process known as electromagnetic induction.

There are various types of transformers available, each with its specific function. These include:

- Step-Up Transformers

- Step-Down Transformers

- Isolation Transformers

- Power Transformers

- Distribution Transformers

- Instrument Transformers

Green electrical transformer box, also known as a green electrical box, is a newer type designed to be more environmentally friendly and energy efficient. These green transformer boxes are a great addition to any electrical system.

The primary constituents of an electrical transformer include the core, windings, insulating materials, transformer oil, and other components that facilitate its function.

The Basic Function of a Transformer

You might wonder how a green transformer box operates to make the electricity that reaches your home safe for use. Transformers play a critical role in the distribution of electricity. They enable the generation and efficient transmission of high-voltage power over long distances, and at the consumer’s location, they facilitate the conversion of electricity to lower voltages, ensuring safe and efficient utilisation.

The transformation process that occurs within the transformer is achieved through two coils, the primary and secondary coil. The energy is transferred from the primary coil, which is linked to the high voltage source, to the secondary coil, which is connected to the load. This process happens through electromagnetic induction, resulting in a lower voltage output suitable for consumer use.

Transformers, therefore, are essential for power distribution and work in conjunction with other electrical equipment, such as an electrical panel, circuit breaker panel, and breaker switches, to ensure safe and efficient power distribution.

Types of Transformers

Having grasped the basic function of transformers, it’s time to delve into the different types. Transformers come in various categories such as:

- Step-Down Transformer

- Step-Up Transformer

- Isolation Transformer

- Iron Core Transformer

- Ferrite Core Transformer

- Toroidal Transformer

- Power Transformer

- Distribution Transformer

- Autotransformer

Each type serves specific functions such as voltage conversion, power transmission, or isolation.

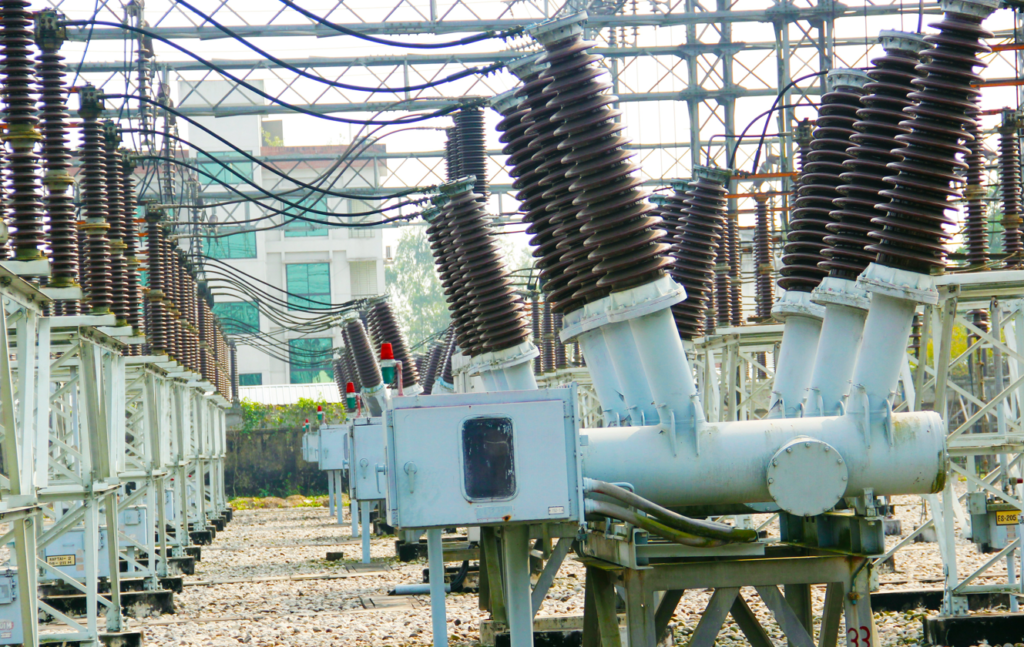

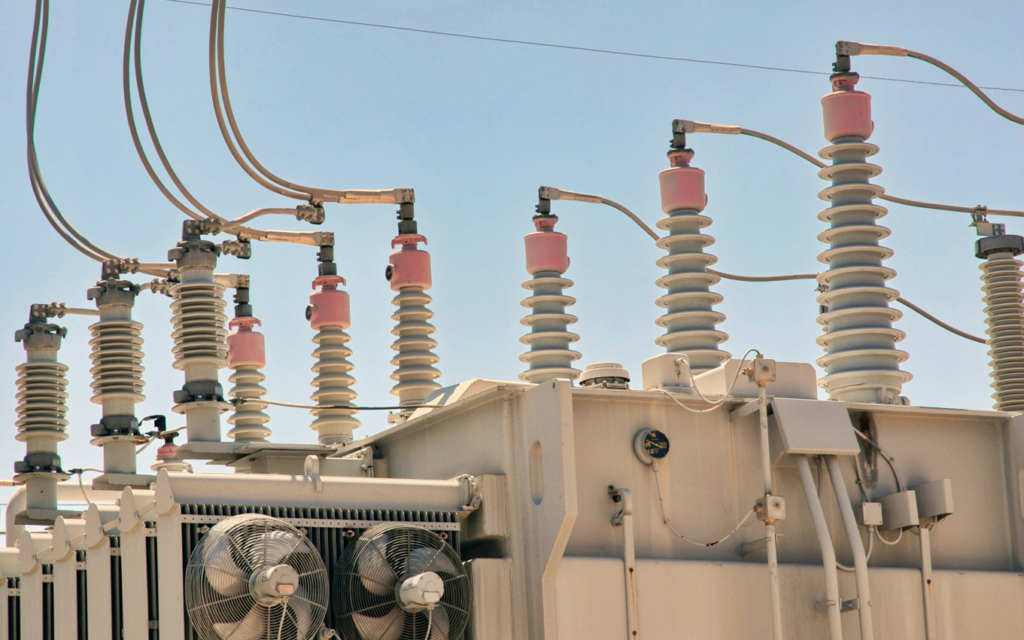

For instance, a power transformer is used in generating stations or substations for conveying large amounts of electric power, usually in high-capacity environments. In contrast, a distribution transformer is designed to efficiently distribute electric power within local power distribution networks. Isolation transformers transfer electrical power between two circuits while maintaining their electrical and physical isolation. Instrument transformers are designed for the measurement of various electrical quantities in AC systems.

The Components Inside a Transformer

Upon examining the internal structure of a transformer, one can find several key components that collectively ensure its operation. The primary constituents include:

- Laminated soft iron core provides a low-resistance path for magnetic flux

- Windings: used for the transfer of energy between circuits

- Insulating materials: prevent leakage

- Transformer oil: used for cooling and insulation

- Tap changer: for voltage adjustment

- Oil conservator: for oil volume management

- Breather: for moisture control

- Cooling tubes: for heat dissipation

These components work together to ensure the efficient and safe operation of the transformer.

The primary coil in a transformer links with the input voltage supply and transforms electrical power into a magnetic field. The secondary coil receives the electrical energy from the primary coil and transmits it to the load, adjusting the voltage level as needed. The performance of a transformer is also influenced by its winding configuration, affecting parameters like:

- voltage ratio

- current rating

- impedance

- leakage flux

The Journey of Electricity: From Generation to Your Home

So, how does the journey of electricity unfold from generation plants to our homes? The journey of electricity from generation to your home involves a complex chain of events. Power generation plants operate by utilising various sources of energy, such as moving water or steam, to rotate turbine blades that drive a generator and generate electricity.

The electricity generated in these power plants is then transmitted over long distances through high-voltage transmission lines. This high-voltage transmission enables the efficient distribution of power over extended distances, minimising resistive losses, and enhancing efficiency. Upon reaching the consumer’s location, utility transformers step down the high-voltage power to lower voltages suitable for safe use in homes.

High Voltage Transmission

The delivery of electricity over long distances heavily relies on high-voltage transmission. The concept of high-voltage transmission enables the efficient distribution of power over extended distances, thereby minimising resistive losses.

High-voltage transmission lines serve the purpose of:

- Transmitting electricity over extended distances

- Producing magnetic fields capable of inducing currents in adjacent conductors

- Potentially causing interference with other systems

High-voltage transmission lines are generally composed of bare wires and do not have any form of insulating coating.

The Role of Utility Transformers in Your Yard

When the power reaches your yard, utility transformers crucially step down the high-voltage power from distribution lines to lower voltages that are safe for use in your home. The function of utility transformers in residential yards is to:

- Step down high-voltage power from distribution lines to lower voltages

- Provide safe power for residential areas

- Typically provide the standard 120 volts required for homes.

The prevalent types of utility transformers utilised in residential yards are pole-mounted or pad-mounted transformers. Utility transformers are connected to the home electrical system through two insulated wires running from the transformer and three wires running to the house. These wires connect to the main circuit breaker and then to copper or alloy bus bars.

The typical lifespan of a utility transformer in a residential yard is over 25 years and can surpass 20 years with appropriate maintenance and servicing.

Ensuring Safety Around Transformer Boxes

Although transformer boxes are vital in our daily lives, they do carry potential risks that warrant our attention. Electrical transformer boxes harbor high voltage and may present considerable safety hazards if mishandled. Safety may be compromised by unintentional vehicular collisions, excavation work, or neglect. Therefore, it is crucial to maintain a minimum distance of 10 feet from transformer boxes.

For safety purposes, it is recommended to maintain a clearance of at least 0.9 meters (approximately 3 feet) around a transformer box. This clearance helps to prevent accidents and ensures utility workers have enough space to work on the boxes when necessary. If you notice any problems with your transformer box, it is crucial to report them to the utility company to ensure efficient resolution of the problem.

Recognising the Hazards

Identifying potential hazards linked to transformer boxes paves the way for ensuring your safety. Typical dangers linked to transformer boxes include:

- The potential for electric shock due to damaged or cut earth leads

- Health hazards associated with low-frequency radiation

- The possibility of transformer fires resulting from mechanical failure and electrical issues.

Tampering with a transformer box can pose significant dangers, including:

- Exposing individuals to live electricity wires, which can have fatal consequences

- Emitting powerful magnetic fields, commonly referred to as EMF (electromagnetic fields)

- Potential health hazards such as miscarriages, leukemia, skin cancer, and multiple sclerosis.

Safe Practices and Clearances

Adhering to safe practices and maintaining clearances around transformer boxes form a critical aspect of ensuring safety. It is important to observe certain safe distances around transformer boxes and adhere to regulations when constructing structures in close proximity to transformer boxes. The regulations dictate that:

- Construction within a registered electricity easement is prohibited without permission

- Metallic structures must not be erected near powerlines

- The minimum clearance distance required from energy infrastructure is 1.5 meters.

Maintaining a clear space of approximately three meters in front of the transformer, refraining from digging beside it, and ensuring that no vegetation or objects are planted or placed within 10 feet in front and 5 feet on the sides and back of the box are all crucial practices for homeowners.

When and How to Report Issues

Being aware of when and how to report issues with transformer boxes could be a lifeline and a safeguard against property damage. Indications of a malfunctioning transformer box may include:

- vibration

- excessive buzzing or humming

- overheating

- visible damage

- changes in insulation colour

- incorrect or lack of voltage

If any of these signs are observed, it is probable that there is a problem with the transformer box.

To report an issue with your transformer box, you can contact the emergency number provided by your utility company or utilise their online reporting system. For example, Ausgrid offers a 24-hour hotline (13 13 88) and an online reporting system.

Installation and Maintenance of Transformer Boxes

For optimal functioning and extended lifespan of transformer boxes, appropriate installation and maintenance are indispensable. The installation process for a transformer box involves:

- Selecting and installing an appropriate fuse or circuit breaker near the transformer

- Connecting it to the input voltage source

- Mounting the electrical box on a completed wall following a detailed guide.

Transformer boxes should be subject to regular maintenance every 3 to 4 years, with interim inspections every 6 months for a range of parameters including dielectric strength, sludge content, acidity, water content, and flash point. Essential maintenance procedures for a transformer box involve conducting half-yearly checks on the transformer oil to assess parameters such as dielectric strength, acidity, water content, and sludge, performing annual cleaning of marshalling boxes, and ensuring the proper operation of space and illumination heaters.

Installation Process

During the installation process of a transformer box, the following safety precautions should be strictly adhered to:

- Ensure proper grounding

- Protect the transformer from damage or tampering

- Use protective gear such as insulated gloves and goggles

- Refrain from opening the box without proper training

- Maintain a safe distance from the equipment

- Avoid digging or installing structures near it to allow access for maintenance.

The installation of a transformer box requires the following tools and equipment:

- Soldering iron

- Hand tools

- Power tools

- Potentially a crane for commercial buildings

It is imperative that an electrician with the appropriate authorisation installs the transformer and selects the correct nominal power.

For a comprehensive installation guide, it is advisable to refer to authoritative sources.

Ongoing Maintenance Needs

Consistent maintenance is key to prolonging the lifespan and ensuring optimal functioning of transformer boxes. The recommended routine maintenance for a home electrical transformer includes:

- Ensuring it is not overloaded

- Performing measurements and testing of different parameters

- For oil-filled transformers, conducting daily oil and temperature checks

The maintenance frequency varies by type, with preventive actions on a scale from daily to yearly, transformer oil checks every six months, and a full overhaul every 5-10 years.

Homeowners are obligated to maintain a clear space of approximately three meters in front of the transformer, refrain from digging beside it, and ensure that no vegetation or objects are planted or placed within 10 feet in front and 5 feet on the sides and back of the box. Utility companies usually carry out specific transformer maintenance tasks once every 3 to 4 years.

Indications that a transformer box needs maintenance or repair comprise of:

- neglected maintenance

- low insulation resistance

- abnormal operating temperatures

- protective devices tripping

- rust

- oil leaks

- damaged components

- a change in operational temperature

- high earth voltage.

Enhancing Home Electrical Systems with Transformer Technology

Incorporating transformer technology into residential electrical systems brings forth multiple benefits, including:

- Efficient voltage conversion

- Regulation

- Energy loss reduction

- Mitigation of electric fire and short circuit risks.

Furthermore, transformer technology contributes to the energy efficiency of a home by:

- Facilitating the efficient transmission of electricity, thereby minimising power loss during transmission

- Providing voltage stability

- Offering overload tolerance

- Helping reduce the risk of electric fire and short circuits

- Contributing to reduced electrical losses, resulting in decreased energy consumption and lower CO2 emissions

- Supporting sustainability efforts.

Surge Protection and Motor Load Management

In addition, transformers offer the following benefits:

- Extra protection against power surges

- Assistance in managing motor loads

- Function in surge protection by utilising shielded isolation transformers to safeguard against common mode noise and low-level transients

- Employment of arresters to protect the primary winding of the transformer

Transformers assist in regulating and managing power loads by aligning the electrical supply with the demand, thereby ensuring grid stability, and preventing motor overloading in home electrical systems. Strategies such as two-speed motors, adjustable speed drives, and load management techniques are employed to maintain loads within an efficient range. Improvements in motor system management, purchasing, training, and routine preventive maintenance are implemented to ensure that motors operate efficiently, further contributing to the overall efficiency of home electrical systems.

Long-Term Cost Savings

Incorporating transformer technology into home electrical systems can yield considerable long-term cost savings. Transformer technology contributes to long-term cost savings in home electrical systems by reducing energy losses and providing energy efficiency, resulting in lower electricity costs over time. The cost-effectiveness of transformer technology in home electrical systems is influenced by several factors, including load characteristics, safety regulations, cost analysis, space optimisation, and the type of transformer core material.

The cost savings on electricity bills associated with the implementation of transformer technology in residential electrical systems can vary, but research indicates that increased electrification can lead to significant savings, with the average household saving approximately $500 per year.

Summary

Electrical transformers play a critical role in our daily lives. They facilitate the efficient transmission and distribution of electricity, ensuring safe and practical voltages for use in homes and businesses. The integration of transformer technology into residential electrical systems provides numerous advantages, including enhanced energy efficiency, surge protection, motor load management, and long-term cost savings.